Autoclave thermal printers and mechanisms

Reliable and precise printing solutions for sterilization and autoclave systems

In both industrial and healthcare environments, autoclaves play a critical role in sterilization processes, ensuring that equipment and instruments are properly disinfected.

Thermal printers integrated into autoclaves are essential for providing precise, detailed printouts of sterilization cycles, offering an accurate record of temperature, time, and pressure during each sterilization process.

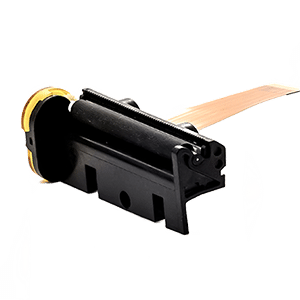

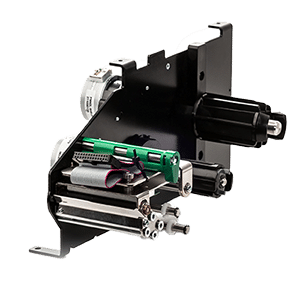

APS thermal printer mechanisms and mechanisms are designed to handle the unique demands of autoclave systems, delivering fast, reliable, and clear prints that meet the strict documentation standards of hospitals, laboratories, and manufacturing plants.

Explore our thermal printer range

Why choose APS for your autoclave printers ?

APS thermal printers and mechanisms are engineered to meet the specific needs of autoclave systems in both healthcare and industrial environments. Here is why APS is the best choice for your autoclave printer needs :

Precise and

reliable data recording

APS thermal printers and mechanisms produce high-resolution printouts that ensure every aspect of the sterilization process is clearly recorded, including temperature, time, and pressure. This accuracy is crucial for regulatory compliance and ensuring the safety of sterilized equipment.

Fast,

real-time printing

APS thermal printers and mechanisms are designed for high-speed printing, ensuring that sterilization records are generated immediately after each cycle. This real-time documentation helps maintain a seamless workflow, especially in environments where sterilization cycles are frequent and must be continuously monitored.

Built for tough environments

Autoclaves operate in environments with high temperatures, steam, and moisture. APS printers and mechanisms are built to withstand these conditions, ensuring durable, long-lasting performance in challenging environments without compromising print quality.

Adaptable media options

APS thermal printers and mechanisms can handle a variety of media, from standard thermal paper to specialized labels used for long-term record-keeping. This versatility ensures that printouts remain legible and durable, even after extended storage.

Custom solutions for autoclave systems

APS offers customized printing solutions to meet the specific needs of your autoclave system. Whether you require custom formats for printouts, specialized paper sizes, or unique media types, APS can provide the right solution to fit your requirements.

Looking for the perfect thermal printer or mechanism for your autoclave system ?

APS offers customized printing solutions designed for autoclaves and sterilization systems, providing accurate, durable, and reliable printing for all your sterilization documentation needs.

The importance of thermal printers for autoclaves

Autoclaves use steam sterilization to disinfect instruments, equipment, and materials by applying high-pressure steam at specific temperatures. Each sterilization cycle must be precisely documented to ensure compliance with industry regulations and to verify that the cycle met the necessary parameters for effective sterilization.

Thermal printers are essential for autoclave systems because they generate detailed records of each cycle, including information such as temperature, cycle time, pressure, and start/stop times.

These printouts are crucial for regulatory compliance, internal audits, and traceability in both healthcare and industrial settings.

By using high-resolution thermal printers, autoclave systems ensure that each printout is accurate, clear, and easy to read. The durability of these printouts is also critical, as sterilization records often need to be archived for long periods of time for regulatory reasons. Thermal printing technology, with its ability to operate in harsh environments without the need for ink or toner, makes it the most practical and reliable solution for autoclaves.

Key factors to consider when selecting a thermal printer or a mechanism for autoclave systems

When choosing a thermal printer or a mechanism for autoclave systems, it is essential to consider factors that ensure accurate, reliable, and durable printouts. Here are key factors to focus on :

- Precision for regulatory compliance

Autoclave cycles need to be meticulously recorded to meet regulatory standards. Select a printer or a mechanism that provides high-resolution printouts with clear, detailed data that can be easily reviewed and archived for compliance purposes.

- Durability in high-temperature environments

Autoclave printers often operate in environments with high temperatures and humidity. Choose a thermal printer or a mechanism that can withstand these tough conditions without sacrificing print quality or reliability.

- Fast, real-time printing

In sterilization workflows, printouts need to be generated immediately after each cycle. Select a thermal printer or a mechanism that offers real-time printing, ensuring that records are available as soon as the sterilization process is completed.

- Media flexibility

Different environments may require different types of media for record-keeping. Choose a printer or a mechanism that supports a range of media, from thermal paper to specialized sterilization labels, to meet the documentation needs of your facility.

- Low maintenance and high reliability

Autoclave systems require printers that are low-maintenance and capable of continuous operation. Thermal printers or mechanisms with minimal maintenance requirements ensure uninterrupted operation, reducing downtime and the need for frequent interventions.

Upgrade your autoclave printing system with APS thermal printers and mechanisms

APS delivers fast, reliable, and efficient printing solutions for autoclave systems, ensuring seamless documentation and high-quality printouts for sterilization processes.