How linerless printers are transforming Labeling processes

Linerless printing solutions are revolutionizing labeling processes, offering a modern alternative to traditional label formats. These innovative labels, which do not rely on backing paper, address some of the most pressing challenges in industries that rely on high-volume labeling. From reducing environmental waste to streamlining operations, linerless technology is emerging as a key driver of efficiency and sustainability.

This article explores how a linerless printer works, its transformative benefits, and its applications across diverse sectors such as retail, logistics, and manufacturing. As businesses look for smarter, greener solutions, linerless printing is paving the way for a future with less waste and greater efficiency.

What are linerless printers?

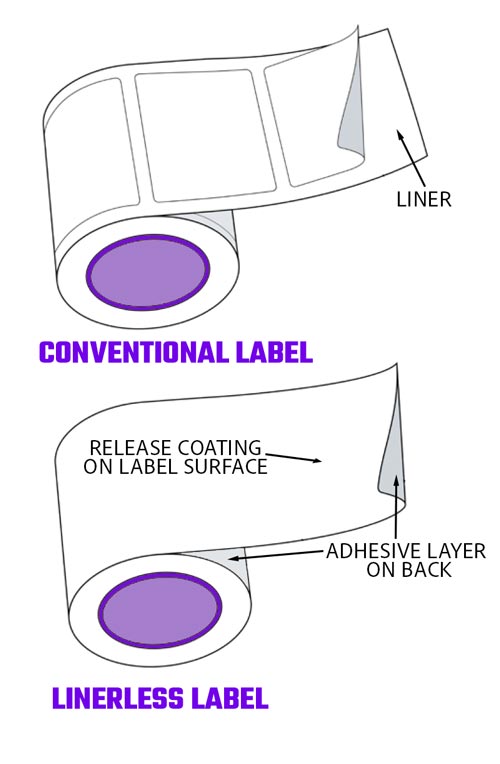

Linerless printing is an advanced labeling technology that eliminates the need for traditional backing paper. In conventional labels, a liner acts as a carrier for the adhesive-backed labels, but it is discarded after application. Linerless labels remove this layer entirely by utilizing a specially designed adhesive that activates during printing or application.

The absence of a liner increases the number of labels per roll, as there is no bulky backing material taking up space.

Additionally, this design simplifies the printing process and reduces waste, making it an eco-friendly option for industries aiming to reduce their environmental footprint. Linerless labels are also versatile, suitable for a wide range of applications, from retail product labeling to logistics and warehousing operations.

Businesses that adopt linerless technology often find themselves better equipped to meet both operational and sustainability goals, as this innovative approach aligns with the growing demand for greener practices and more efficient production methods.

Key benefits of linerless printing solutions

As industries become more reliant on mobile and space-constrained devices, the demand for compact, high-performance thermal printers is rapidly increasing. Whether it’s a mobile POS system, a self-service kiosk, or a medical device, smaller, more powerful thermal printers are essential to ensuring smooth operations in limited spaces.

Environmental impact

One of the most significant advantages of linerless printing is its positive effect on the environment. Traditional label liners are often discarded after use, contributing to landfill waste and additional disposal costs. Linerless technology eliminates this issue entirely, enabling businesses to lower their environmental footprint.

By reducing the amount of waste generated in labeling processes, companies can also enhance their sustainability efforts and align with eco-conscious consumer expectations. As global industries increasingly prioritize environmental responsibility, linerless printing offers a practical solution to minimize waste without compromising performance.

Cost efficiency

Linerless labels provide substantial cost savings across several aspects of the labeling process. Without liners, each roll holds more labels, reducing the frequency of roll changes, storage requirements, and shipping costs. This increased roll capacity translates into fewer interruptions during production, boosting overall efficiency.

Additionally, the absence of liner waste means companies save on disposal costs, further enhancing the economic benefits. Whether applied in high-volume production lines or smaller-scale operations, linerless labels offer long-term cost reductions that make them an attractive option for businesses seeking greater profitability.

Enhanced operational efficiency

Linerless printing simplifies operations by eliminating the need to handle and dispose of liner material. This streamlining of the labeling process not only reduces downtime but also minimizes maintenance requirements for printing equipment, as there is no liner residue to manage.

Moreover, linerless labels can be customized more easily for variable data printing, making them ideal for dynamic applications such as logistics tracking or retail price adjustments. These efficiencies improve both speed and accuracy, ensuring that operations run smoothly even under demanding conditions.

Applications of linerless printers

Retail And E-Commerce

Linerless printing solutions are increasingly popular in the retail and e-commerce sectors, where efficient labeling processes are crucial. From product labels and price tags to barcodes and promotional stickers, linerless labels provide a versatile and sustainable option. Their ability to print variable data makes them ideal for applications like dynamic pricing or customized offers.

Additionally, the increased roll capacity of linerless labels reduces downtime caused by frequent roll changes, allowing retailers to maintain fast-paced operations. With e-commerce growth driving higher labeling demands, linerless technology supports scalability without sacrificing efficiency or sustainability.

Logistics And Warehousing

In logistics and warehousing, where shipping labels and inventory tracking are critical, linerless printing offers significant benefits. By eliminating liner waste, companies can streamline their processes and reduce clutter in busy warehouses.

Linerless labels are particularly well-suited for variable data printing, which is essential for applications like parcel tracking and real-time inventory updates. The technology’s ability to print on-demand ensures accurate labeling, reducing errors and improving overall operational efficiency.

Food And Beverage Industry

The food and beverage industry relies heavily on labeling for compliance, branding, and traceability. Linerless labels provide an eco-friendly solution for high-volume applications such as packaging labels, ingredient lists, and expiration dates.

Their waste-free design aligns with the industry’s increasing focus on sustainability, while their flexibility supports rapid label changes for seasonal or promotional products. Linerless printing also meets food safety standards, making it a practical choice for both manufacturers and distributors.

Healthcare

In healthcare, linerless printing solutions play a vital role in ensuring accurate and efficient labeling. Applications include prescription labeling, patient identification tags, and medical equipment labels. The waste-free design reduces clutter in sensitive environments like pharmacies and hospitals, improving workflow efficiency.

Linerless labels also support on-demand printing, essential for prescription labels that must include variable data such as patient details, dosage instructions, and expiration dates. Their reliability and compatibility with high-speed systems make them an indispensable tool in maintaining safety and compliance in the healthcare sector.

Industrial applications

Industrial environments, such as manufacturing plants and chemical production facilities, require durable labeling solutions that can withstand harsh conditions. Linerless labels, with their high-quality adhesive and customizable printing options, are ideal for heavy-duty applications.

They are used for labeling machinery, tools, and products, ensuring clear identification and compliance with safety standards. The elimination of liner waste further enhances efficiency in industrial settings, where sustainability and streamlined operations are priorities.

Challenges and solutions in adopting linerless printing

Initial investment costs

One of the main barriers to adopting linerless printing solutions is the upfront cost of upgrading equipment. Many businesses may hesitate to replace existing printers or invest in retrofitting. However, the long-term savings from reduced material use, storage costs, and waste disposal often offset the initial expense.

Manufacturers of linerless-compatible printers are also working to make these systems more accessible, providing cost-effective options and robust support to ease the transition for businesses.

Adhesive compatibility

Adhesive technology is critical to the success of linerless printing. Without a liner, the adhesive must remain effective without causing issues such as sticking prematurely during the printing process.

To address this challenge, advancements in adhesive formulations have improved the reliability and performance of linerless labels. These innovations ensure that the adhesive activates only during application, making the labels suitable for a wide range of surfaces and environments.

Equipment Upgrades

Older printing equipment may not be compatible with linerless labels, requiring businesses to either retrofit existing machines or invest in new ones. While this may initially seem daunting, many manufacturers now offer retrofitting solutions that allow companies to adapt their current systems without significant disruption.

Furthermore, linerless-compatible printers are designed with user-friendly features that simplify the adoption process, ensuring a smooth transition for businesses aiming to modernize their labeling operations.

The future Of linerless printing solutions

The linerless printing market is poised for significant growth as businesses increasingly prioritize sustainability, cost-efficiency, and operational excellence. According to industry reports, the demand for eco-friendly solutions is driving innovations in linerless label materials, adhesive technologies, and printing equipment.

Emerging trends, such as the integration of IoT and smart labeling capabilities, further enhance the potential of linerless printing. These advancements enable real-time tracking, improved inventory management, and greater customization. Additionally, expanding applications in sectors like healthcare, food safety, and logistics highlight the versatility of linerless labels.

As industries worldwide adopt stricter environmental standards, linerless printing will play a crucial role in meeting sustainability goals. The future of labeling lies in technologies that balance performance with environmental responsibility, and linerless solutions are at the forefront of this transformation.

APS’s Expertise In linerless printers

APS has a proven track record of innovation and excellence in thermal printing technology, making it a leader in the linerless printing space. With over two decades of expertise, APS specializes in designing and manufacturing printers that cater to the unique demands of linerless label applications.

APS’s linerless-compatible printers are engineered to ensure precision, durability, and reliability across a wide range of industries, including healthcare, logistics, retail, and industrial environments. Our products feature advanced adhesive handling mechanisms, ensuring smooth and efficient printing without the risk of adhesive buildup or jamming.

In addition to offering cutting-edge standard solutions, APS excels in delivering customized printers tailored to specific operational requirements. Whether you need a compact printer for limited space or a high-speed model for large-scale production, APS combines innovation with customer-focused design to deliver unparalleled solutions.

By partnering with APS, businesses can embrace the benefits of linerless technology, reduce waste, and achieve operational excellence with confidence.

Take Your Labeling to the Next Level !

Discover how linerless printing solutions can revolutionize your processes. Contact APS today to explore our innovative, sustainable, and custom-tailored thermal printing solutions.