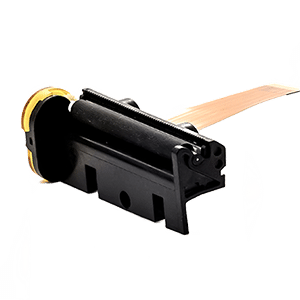

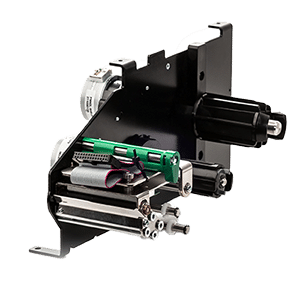

Baggage tag thermal printers and mechanisms

Fast and efficient printing solutions for boarding pass issuance in transportation hubs

In airports and other transportation hubs, baggage tag printing is essential for tracking luggage throughout the journey. Whether at check-in desks or self-service kiosks, thermal printer mechanisms are at the core of every baggage tag printer, ensuring that labels are printed quickly and accurately.

APS’s thermal printers and mechanisms are designed to meet the high-volume demands of modern baggage systems, offering precise printing, reliable cutting, and smooth operation, even in the busiest environments.

From compact check-in stations to large-scale baggage handling systems, APS printers and mechanisms are built to ensure error-free, durable tag printing on a wide range of labels.

Explore our thermal printer range

Why choose APS for your baggage tag printing mechanism?

APS thermal printers and mechanisms are tailored to meet the demanding requirements of baggage tag printing, providing flexibility, precision, and reliability across diverse airport and transportation environments. Here is why APS is the ideal choice for your baggage tag printing needs:

Superior print quality

With the need for clear, scannable barcodes and legible text on baggage tags, APS printers and mechanisms offer high-resolution printing, ensuring that tags remain sharp, durable, and easy to read throughout their journey, from check-in to final destination.

High-speed printing

In the fast-paced environment of airports, speed is crucial. APS printers and mechanisms deliver high-speed performance, processing large volumes of baggage tags rapidly, reducing waiting times and keeping operations running efficiently.

Advanced sensors and blackmark detection

APS printers and mechanisms are equipped with highly accurate sensors and blackmark detection technology, ensuring that each baggage tag is perfectly aligned and printed without errors.

Precise and reliable cutting

APS thermal printer and mechanisms feature high-precision cutters that handle various label thicknesses, ensuring clean, accurate cuts on every baggage tag. This reduces the risk of misalignment or jams, ensuring that every tag is properly sized and ready for application.

Compatibility with various systems

APS printers and mechanisms are designed to seamlessly integrate with existing airport systems and CUPPS-compliant infrastructure, making it easy to incorporate them into self-service kiosks and check-in desk systems. This adaptability ensures smooth integration and consistent performance across platforms.

Bespoke project capabilities

At APS, we understand that each transportation hub may have unique requirements. We offer customized printing solutions tailored to your specific needs, from accommodating special label sizes to integrating advanced features.

Looking for the perfect thermal printer and mechanism for your baggage tag printing needs?

APS offers customized thermal printing solutions that ensure fast, precise, and durable label printing for baggage handling systems in airports and transportation hubs.

The importance of thermal printer for baggage tag printing

When printing baggage tags, the primary requirements are speed, precision, and reliability. Thermal printer mechanisms excel in this role, providing high-resolution printouts of important information such as the flight number, destination, and barcodes for tracking.

For baggage tag applications, thermal printing ensures that labels are smudge-proof and resistant to wear, a critical feature since luggage often passes through multiple handling stages and environments.

Labels need to remain legible from the moment they are printed until the final destination, ensuring accurate tracking and smooth processing.

Moreover, label durability is paramount, as tags must endure friction, varying temperatures, and movement without the risk of the information fading or becoming unreadable. This is where APS thermal printers and mechanisms excel: by producing clear, reliable baggage tags that withstand these conditions while ensuring minimal maintenance and low operating costs.

Key factors to consider when selecting a thermal printer or a mechanism for baggage tag printing

Selecting the right thermal printer or mechanism for baggage tag printing requires careful consideration of both performance and operational efficiency. Here are the most important factors:

- Cutting accuracy and reliability

One of the most critical components for baggage tag printing is the cutter. A robust and reliable cutting mechanism ensures that each label is cut to the exact specifications, preventing paper jams or tag misalignment. The quality of the cut impacts not just the speed of operations, but also the ability to handle high volumes of luggage in airports or transportation hubs. - Compatibility with various label types

Airports may use different types of labels depending on the system and airline. It’s essential to choose a mechanism that can handle multiple label sizes, formats, and thicknesses, ensuring flexibility in baggage tag printing. APS thermal printers and mechanisms provide the versatility needed to print on custom or standard labels without compromising performance. - High-volume printing performance

In busy transportation hubs, printing mechanisms need to handle high print volumes without frequent maintenance. Look for a thermal printer or mechanism that is built for continuous use, capable of maintaining consistent print quality even during peak travel seasons. The ability to operate under pressure with minimal downtime is crucial for efficient baggage management - Low maintenance and operational costs

Reducing downtime and maintenance is key to maintaining smooth operations. APS thermal printers and mechanisms are designed for long-term reliability, with components that require minimal intervention and service. The absence of ink or toner also helps reduce running costs, making APS printers and mechanisms a cost-efficient solution for baggage tag printing. - Seamless integration and adaptability

Whether being integrated into an existing baggage handling system or a new self-service kiosk, the mechanism must be easy to install and maintain. APS thermal printers and mechanisms are designed to fit a wide variety of transportation systems, offering flexible installation options while ensuring they meet the demands of both high-speed desk setups and compact kiosks.

Upgrade your baggage tag printing systems with APS thermal printers and mechanisms

APS delivers fast, reliable, and efficient printing solutions for baggage tag applications, ensuring smooth operation and high-volume performance in both kiosks and check-in desks.