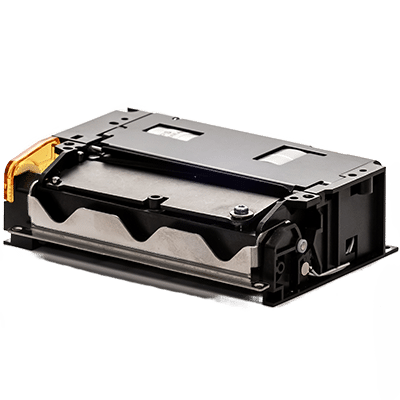

Linerless Printers

Waste-free thermal printing with variable-length labels

Highlights and features

Compact and robust designs for easy integration.

Eliminate liner waste enhancing safety by reducing waste material remaining on warehouse floors and work areas during production.

Environmentally friendly, waste-free printing.

Featuring compact designs, advanced paper handling, and reliable thermal technology, APS linerless printers deliver high-quality results while minimizing the environmental impact.

17 products

BESPOKE THERMAL PRINTER PROJECTS

Let’s engineer your linerless printer together

APS understands that different industries have specific needs when it comes to linerless label printing. That is why we offer customized linerless printing solutions designed to integrate seamlessly into your existing systems.

Whether you are in retail, logistics, food service, or manufacturing, our printers can be tailored to meet the unique demands of your operation.

For example, in the food service industry, where freshness and accurate labeling are crucial, our linerless printers provide the flexibility to print variable-length labels that include all necessary information, such as expiration dates and nutritional details. In logistics, our printers are integrated into shipping systems to produce labels that fit various package sizes, ensuring that labels are always the right size and format for the job

What is a Linerless Printer?

A linerless printer is a specialized type of label printer designed to work with linerless label rolls, which are labels without the traditional backing paper, or liner.

Unlike conventional labels, which come with a peel-off liner that serves as a backing material to protect the adhesive, linerless labels adhere directly to themselves in the roll. This eliminates the need for a wasteful backing liner, making linerless printers an eco-friendly and cost-effective solution.

How linerless printers work

Linerless printers are equipped with advanced thermal printing technology that enables them to print directly on the adhesive-backed labels.

The printer carefully handles the labels to avoid sticking during the printing process, using specially designed mechanisms that ensure smooth feeding and cutting of the labels.

The absence of a liner means that these printers need to manage the adhesive side of the label carefully, ensuring that the labels are printed and dispensed without causing jams or other issues.

One of the key features of linerless printers is their ability to dynamically adjust the label length. Unlike traditional labels, which are pre-cut to specific sizes, linerless labels can be printed at variable lengths, depending on the information that needs to be displayed.

This flexibility reduces label waste and allows businesses to print only what is needed, improving overall efficiency and reducing costs.

Specificities of linerless printer usage

Environmental Benefits:

- Waste Reduction: By eliminating the liner, linerless printers significantly reduce the amount of waste generated in the labeling process. This not only helps businesses reduce their environmental footprint but also lowers disposal costs.

- Resource Efficiency: Linerless labels use less material overall, making them a more sustainable option. Businesses that prioritize eco-friendly practices can benefit from the reduced environmental impact of using linerless labels.

Cost Savings:

- Lower Material Costs: Without the need for a liner, businesses can save on material costs. Additionally, the flexibility of printing labels at custom lengths reduces label waste, leading to further cost savings.

- Increased Roll Capacity: Linerless label rolls typically contain more labels per roll compared to traditional rolls with liners. This means fewer roll changes, reduced downtime, and lower shipping and storage costs.

Enhanced Efficiency:

- Custom Label Lengths: Linerless printers allow for on-demand printing of custom label lengths, making them ideal for applications where variable information needs to be printed. This is particularly useful in industries like logistics, retail, and food service, where products and packaging often vary in size.

- Space Savings: The absence of a liner means that linerless label rolls are more compact, allowing for more efficient use of storage space and reducing the frequency of roll changes.

Considerations and challenges:

- Handling Adhesive: Because the labels are self-adhesive, linerless printers require precise handling to avoid issues such as label sticking or jamming. The printer modules are specifically designed to manage the adhesive side carefully, ensuring smooth operation.

Find the perfect printing solution for your needs.

Whether you’re a small business or an industry leader, we offer customized solutions that drive success. Request a personalized quote today and unlock the power of precision and efficiency with APS Printers.

Ready to take the next step? Click below to request a personalized quote and let our dedicated team empower your printing endeavors. Experience the APS Printers difference today.

Get your custom quote